Introduction

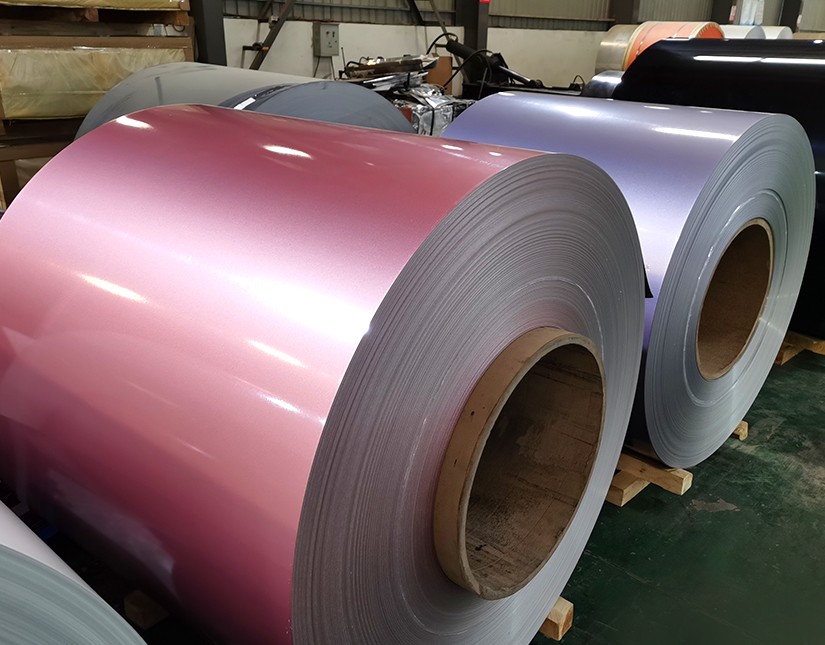

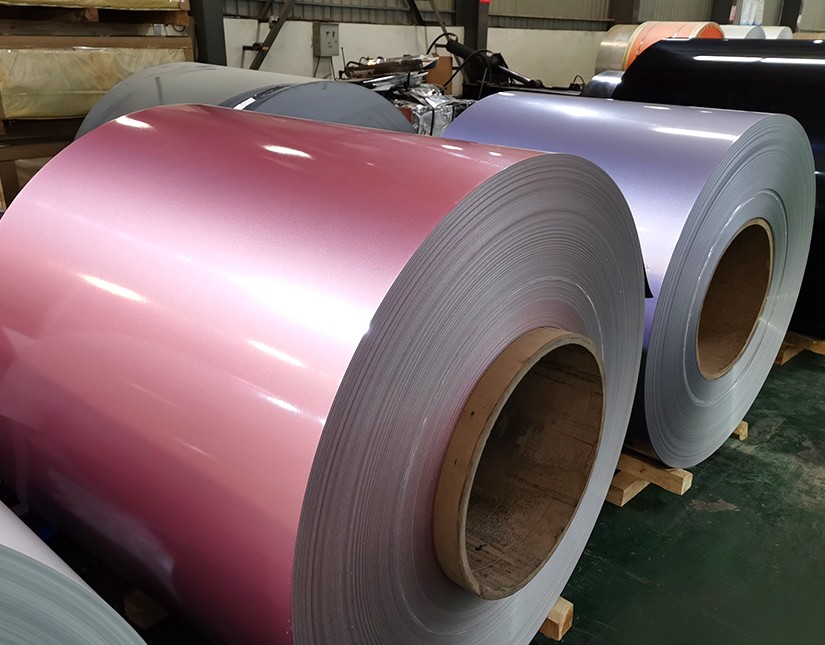

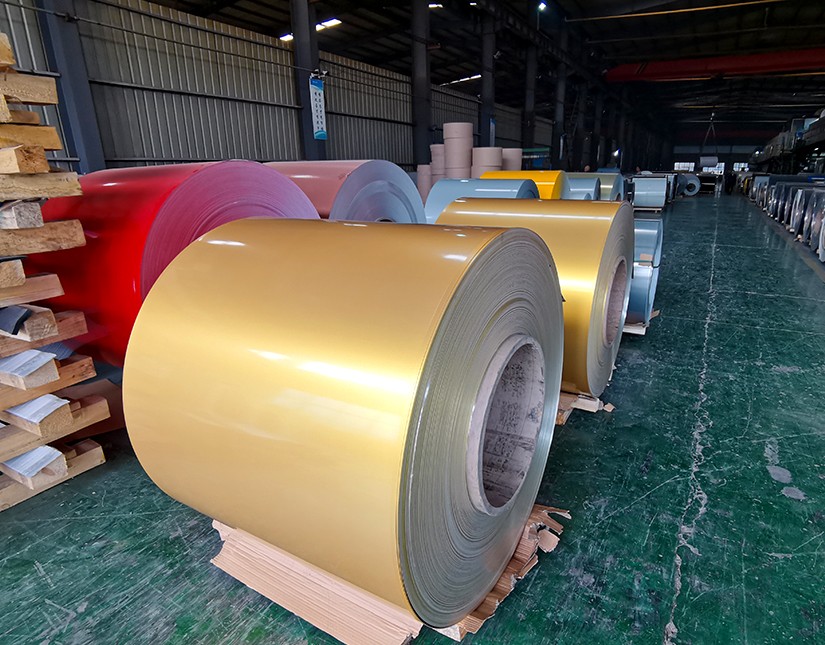

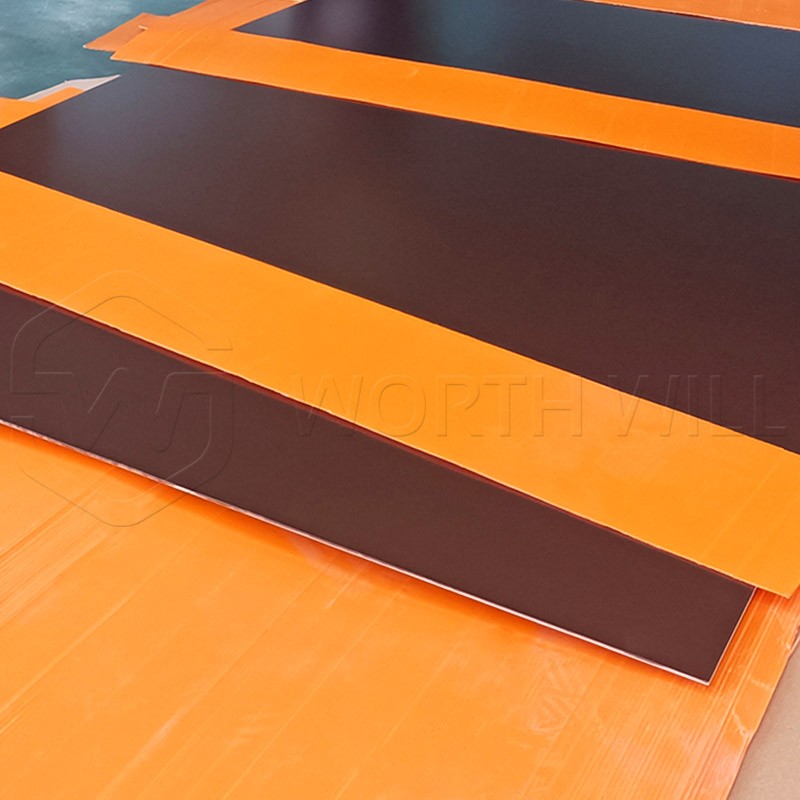

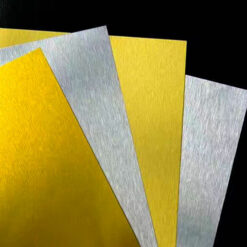

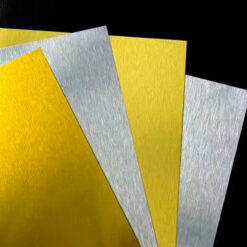

What is PVDF Coated Aluminum?

PVDF (Polyvinylidene Fluoride) coating is a fluorocarbon-based finish applied to aluminum surfaces. Composed of vinylidene fluoride polymers, this advanced coating offers exceptional chemical stability, UV resistance, and weatherproofing. Unlike standard PE (polyester) coatings, PVDF ensures long-term color retention and structural integrity, even in harsh environments.

Key Features & Advantages

Superior Weather Resistance: Withstands extreme UV exposure, rain, snow, and temperature fluctuations, making it ideal for outdoor applications.

Enhanced Durability: Resists corrosion, scratches, and abrasions while maintaining a smooth, easy-to-clean surface.

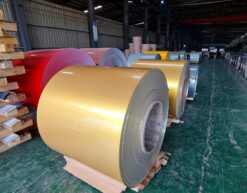

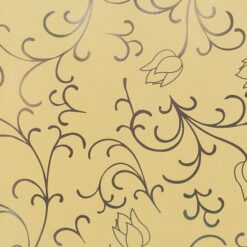

Vibrant Color Retention: PVDF’s advanced pigments retain brightness and gloss for decades, reducing maintenance costs.

Lightweight & Flexible: Easy to fabricate for diverse designs, from curved façades to intricate signage.

Eco-Friendly & Low Maintenance: Non-porous surface prevents dirt buildup, requiring minimal cleaning.

Applications of PVDF Coated Aluminum Coil & Sheet

-

Architectural Cladding: Exterior walls, curtain walls, and roofing systems for commercial and residential buildings.

-

Signage & Branding: Durable outdoor billboards, exhibition displays, and decorative panels.

-

Transportation: Exterior panels for buses, trucks, and rail vehicles.

-

Interior Design: Ceilings, partitions, and furniture with a premium finish.

-

Industrial Uses: HVAC systems, machinery guards, and corrosion-resistant components.

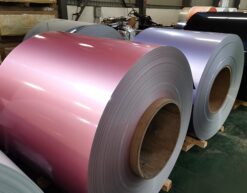

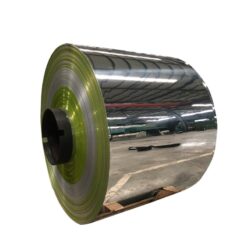

Parameter

| Item | Alloy | Temper | Thickness | Width | MOQ |

|

PVDF Coated Aluminum Coil&Sheet |

1000, 3000, 5000, 6000 series etc. or as per customer’s requests |

O – H112, T3 – T8, T351 – T851 etc. or as per customer’s requests |

0.06mm~1.0mm or as per customer’s requests |

20mm~1590mm | 3 TONS |