Introduction

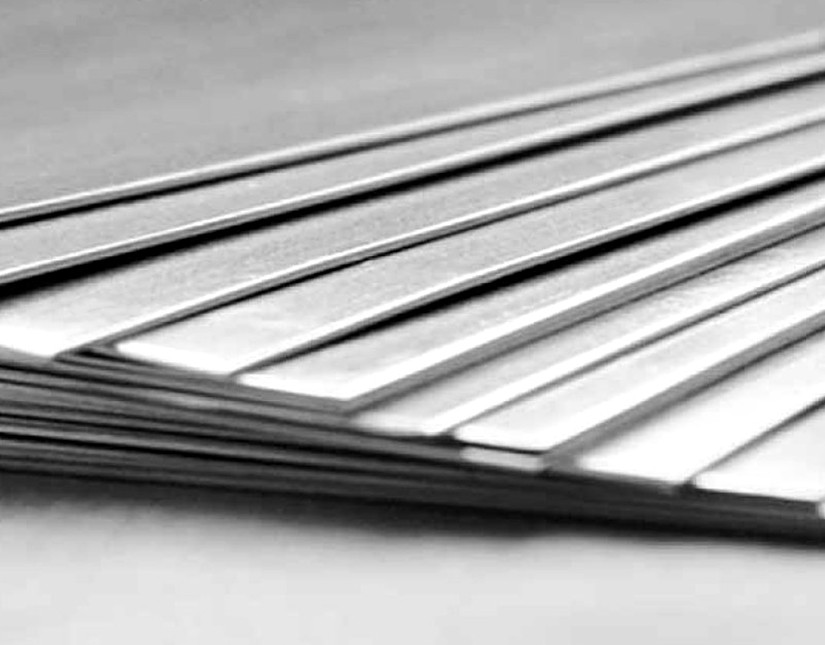

Top Applications of 3105 Aluminum Sheet/Plate/Coil

-

Architectural Cladding: Roofing sheets, ceiling panels, and wall partitions with paint-ready surfaces.

-

HVAC Systems: Durable baffles, air ducts, and ventilation louvers.

-

Packaging Solutions: Deep-drawn aluminum caps, bottle stoppers, and can ends.

-

Rainwater Management: Anti-leak eaves, downspouts, and custom gutter profiles.

Key Features of 3105 Alloy Aluminum

-

41% IACS Electrical Conductivity: Ideal for components requiring energy efficiency, such as lamp heads and heat sinks.

-

Enhanced Corrosion Resistance: Chromium additive ensures long-term durability in humid or marine environments.

-

Multi-State Flexibility: Available in fully soft (O), semi-hard (H12/H14), and other tempers to match project requirements.

-

Weldable & Formable: Perfect for sheet metal fabrication of gutters, partitions, bottle caps, and louver blades.

Why Choose Our 3105 Aluminum Coil?

-

Precision Slitting: Tight tolerance control (±0.01mm) for complex roll forming.

-

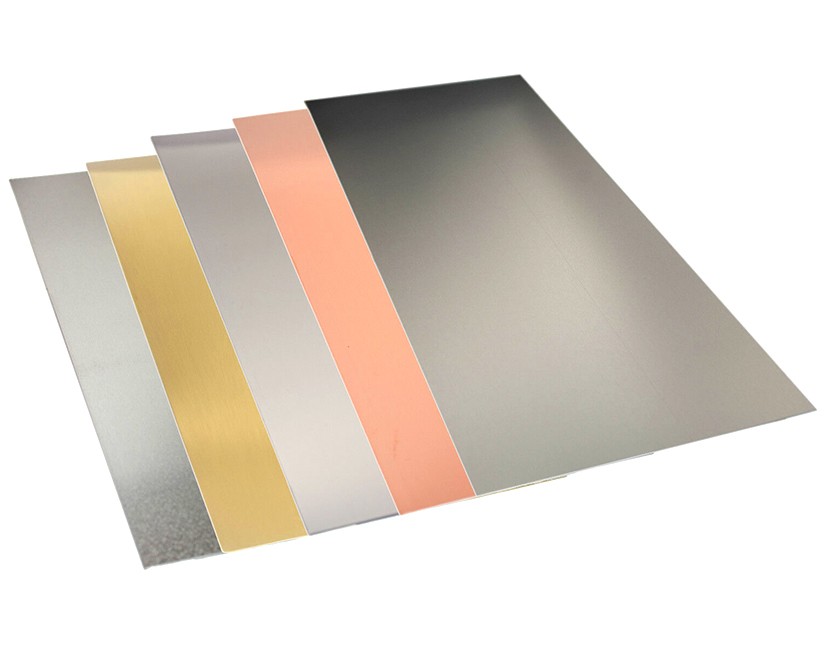

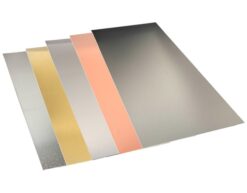

Surface Options: Mill finish, embossed, or color-coated substrates.

-

Global Logistics: 15–25 days lead time with moisture-proof packaging.

FAQs About 3105 Alloy

Q: Is 3105 aluminum suitable for coastal roofing?

A: Yes, its manganese-chromium alloying resists saltwater corrosion effectively.

Q: Can you supply perforated 3105 aluminum sheets?

A: We offer laser-cut and stamped patterns for acoustic panels/sunshades.

Parameter

| Product Name | 3105 aluminum sheet&coil |

|---|---|

|

Temper |

0、H12、H14、H16、H18、H19、H22、H24、H26、H28、H112 etc |

|

Thickness(mm) |

0.1-500 |

|

Width(mm) |

100-2200 |

|

Length(mm) |

500-11000 |