Introduction

Applications of 6063 Alloy Aluminum Plate/Sheet/Coil

1. 6063 Aluminum for Architectural Systems

-

Curtain wall panels

-

Window & door framing

-

Decorative column cladding

2. Consumer Electronics

-

LED light housings

-

Appliance trim

3. Industrial Extrusions

-

Solar panel frames

-

HVAC ducting

Key Advantages of 6063 Alloy Aluminum

-

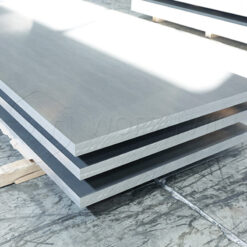

Enhanced Surface Quality: 6063 aluminum sheet features exceptional smoothness (Ra ≤0.4μm) – ideal for anodized facade panels and precision trim parts.

-

Optimal for Extrusion: With higher magnesium content (0.45-0.9%) than 6061, our 6063-T5 aluminum plate delivers 20% better formability for complex cross-sections.

-

Architectural-Grade Durability: MEETS AAMA 611-2020 specifications for curtain walls and window systems with 35+ years service life in coastal climates.

FAQs About 6063 Aluminum

Q: 6063 vs 6061 aluminum: Which is better for painting?

A: 6063’s smoother surface achieves better paint adhesion with 10-15% lower post-treatment costs.

Parameter

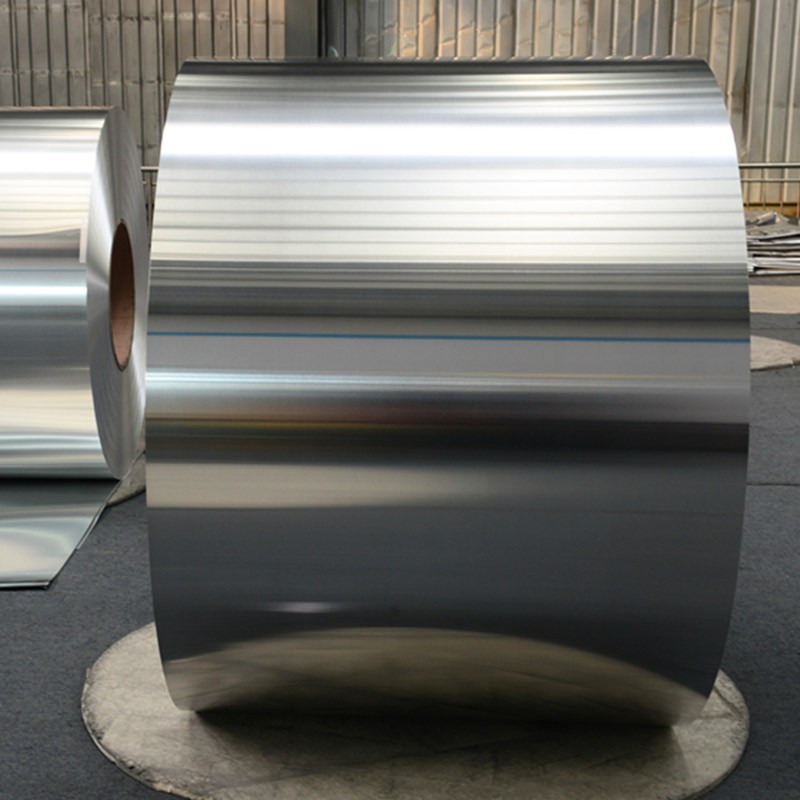

| Product Name | 6063 aluminum sheet&coil |

|---|---|

|

Temper |

O,T4,T5,T6,F |

|

Thickness(mm) |

0.3-500 |

|

Width(mm) |

500-2200 |

|

Length(mm) |

500-11000 |

| Surface Treatment | Mill finish, brushed, anodized |

| Key Certification | IOS, SGS, CE, GB/T 5237.1-2020, AS/NZS 1866 |