Introduction

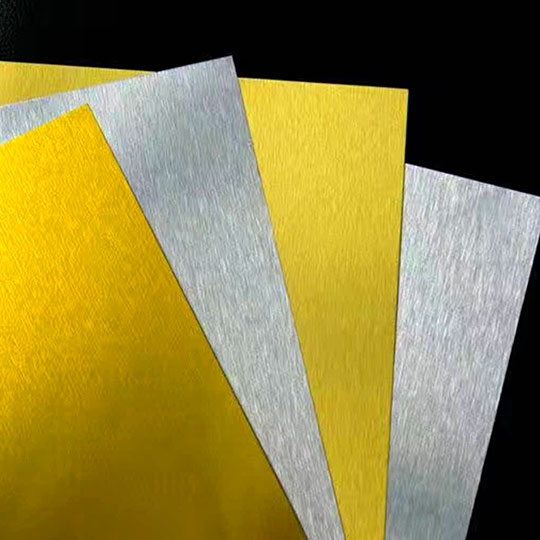

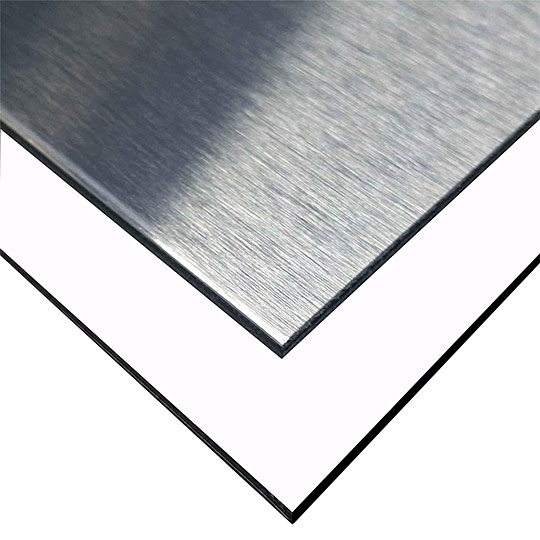

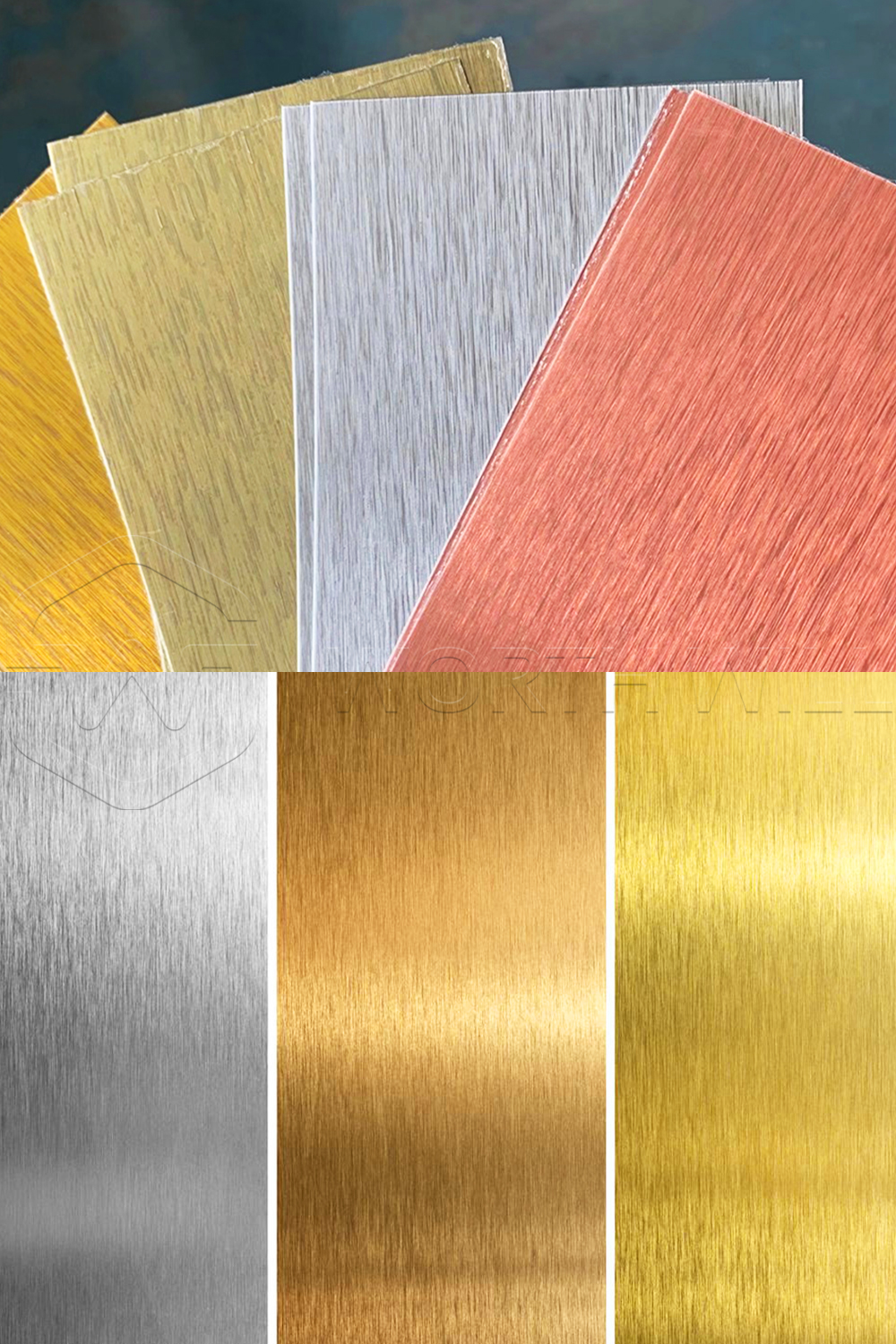

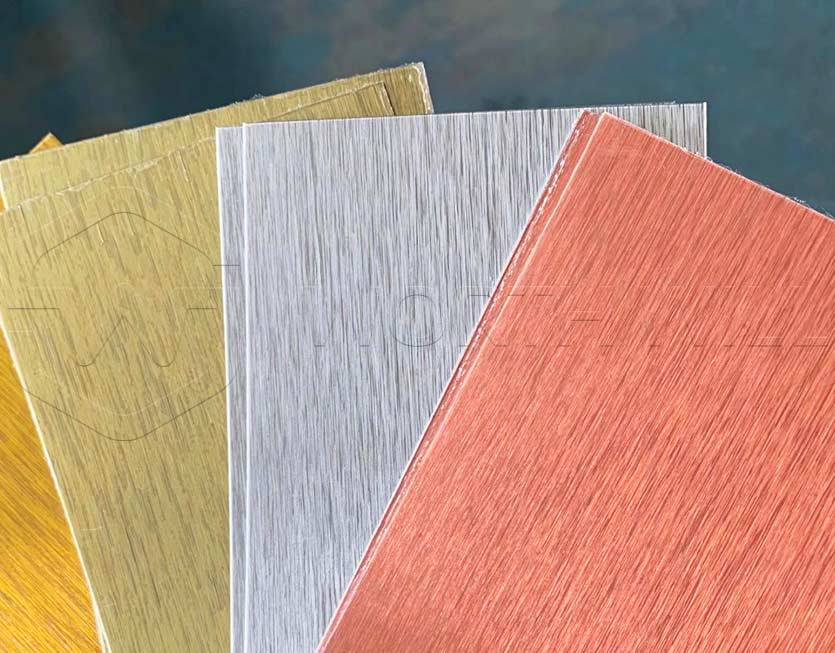

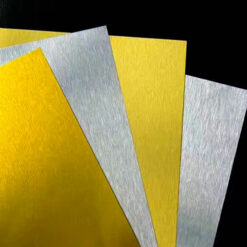

Key Features of Brushed Aluminum Sheet/Coil

-

Premium Brushed Texture: Achieve consistent cross-grain or directional patterns through advanced mechanical brushing technology (Ra 0.05-0.5μm adjustable).

-

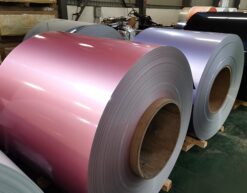

Customized Protection: Available with PVDF or PE coating options – creating genuine brushed coated aluminum products with enhanced UV/corrosion resistance.

-

Precision Dimensions: Thickness: 0.03-1.35mm | Width: 900-1350mm | Temper: H14-H32 | Alloy: 1000/3000/5000 series

-

Multi-Sector Certification: ASTM B209/AMS 4037 compliant | RoHS/REACH approved | LEED-compatible sustainable manufacturing

Superior Applications of Brushed Finish Aluminum

-

Architectural cladding & decorative panel systems

-

Luxury appliance surfaces (refrigerators, ovens, elevators)

-

Automotive trim & marine components

-

Signage frameworks & exhibition displays

Competitive Advantages of Brushed Coated Aluminum

-

30% Longer Finish Integrity vs. industry standards

-

Full temper control for optimal formability

-

Custom pattern/texture development service

-

2-hour technical consultation (metal finishing experts)

Quality Assurance

-

4-stage surface inspection system

-

Protected edge packaging

-

Batch-specific test reports

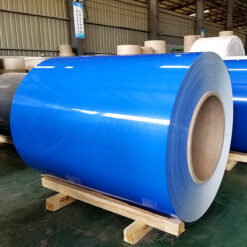

Parameter

| Item | Alloy | Temper | Coating thickness | Base aluminum size | Capacity / month |

|---|---|---|---|---|---|

|

Brushed Aluminum Coil/Sheet |

1050/1060/1100 or as per customer’s requests |

H24 or as per customer’s requests |

As per customer’s requests |

0.03-1.35 mm x 900-1350 mm x C |

500 tons |